As we enter 2024, the North American space industry is poised for a remarkable journey into the cosmos. With an array of exciting missions and projects on the horizon, this year promises to be pivotal for space exploration. However, what often goes unnoticed is the critical role that North American manufacturing plays in enabling these extraordinary space endeavours. This blog post will delve into the most anticipated North American space events of 2024 and shed light on how manufacturing drives these cosmic ambitions.

Artemis Mission: Returning to the Moon

The Artemis program, led by NASA, is one of the decade’s most eagerly anticipated space missions. Building upon the legacy of the Apollo program, Artemis aims to return humans to the Moon to establish a sustainable presence. While this mission focuses on astronauts, rockets, and lunar habitats, manufacturing is the unsung hero that makes it all possible.

Space Launch System (SLS): The Backbone of Artemis

The Space Launch System, or SLS, is the most powerful rocket ever built by NASA. This behemoth of a rocket will be responsible for carrying astronauts and cargo to the Moon. The manufacturing of the SLS involves thousands of components, including engines, boosters, and fuel tanks. Companies like Boeing, Northrop Grumman, and Aerojet Rocketdyne are vital players in the manufacturing process, ensuring that each component is built to the highest standards of quality and reliability.

Orion Spacecraft: The Lunar Taxi

The Orion spacecraft is designed to transport astronauts to and from the Moon. Its manufacturing involves advanced materials and cutting-edge technology. Lockheed Martin is the primary contractor responsible for building the Orion spacecraft, which serves as a testament to North American manufacturing prowess. The Orion spacecraft is a marvel of engineering, providing astronauts with a safe and comfortable environment during their lunar missions.

Commercial Space Ventures

While NASA remains at the forefront of space exploration, commercial space ventures are rapidly gaining ground. Companies like SpaceX, Blue Origin, and Virgin Galactic are making headlines with their ambitious plans. Manufacturing is at the heart of these ventures, ensuring that the hardware and technology required for space travel are up to the task.

SpaceX’s Starship: Revolutionizing Space Travel

Under Elon Musk’s leadership, SpaceX is on a mission to revolutionize space travel with its Starship spacecraft. This fully reusable spacecraft is being manufactured in Texas and Florida, and it aims to carry humans to Mars and beyond. The manufacturing processes behind Starship involve innovative techniques and materials, making it a prime example of North American manufacturing pushing the boundaries of what’s possible in space exploration.

Blue Origin’s New Glenn: A Heavyweight Rocket

Blue Origin, founded by Jeff Bezos, is working on the New Glenn rocket, a heavy-lift launch vehicle designed to carry payloads and humans to space. The manufacturing of New Glenn involves a wide range of components, from engines to avionics, representing a significant investment in North American space manufacturing capabilities.

International Collaboration: Gateway to the Stars

Space exploration is often a collaborative effort, with nations worldwide working together to achieve common goals. The Lunar Gateway, a planned space station orbiting the Moon, is a testament to international cooperation in space exploration. North American manufacturing companies are playing a crucial role in constructing and assembling Gateway modules.

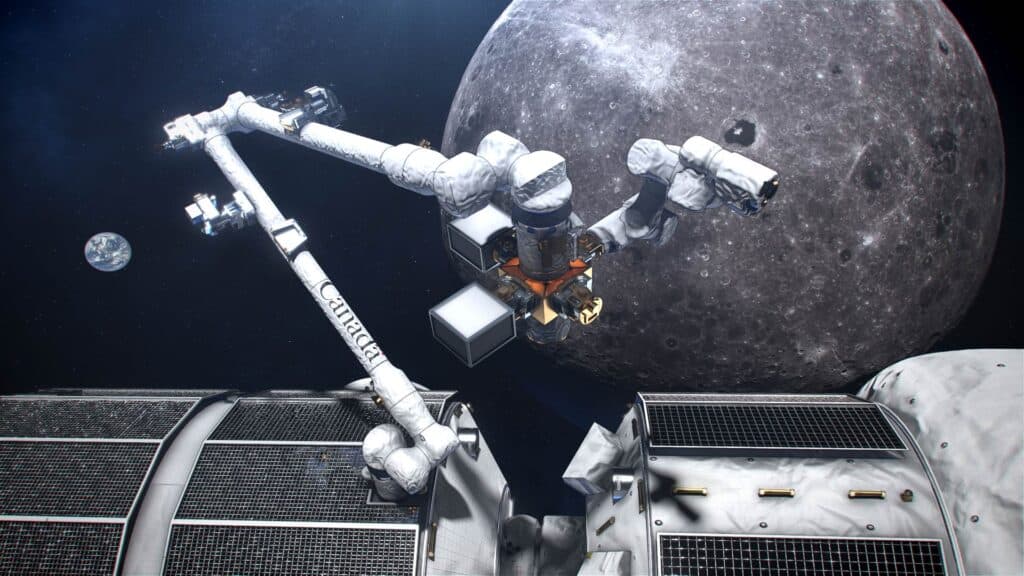

Canadarm3: Canada’s Contribution to Gateway

Canada is known for its expertise in robotics, and the Canadarm3 is a prime example. This robotic arm is being manufactured by MDA (MacDonald, Dettwiler and Associates), a Canadian aerospace company. Canadarm3 will play a vital role in assembling the Gateway, showcasing the importance of North American manufacturing in international space endeavours.

Space Tourism: A New Frontier

In recent years, space tourism has captured the public’s imagination. Companies like Virgin Galactic and Blue Origin are making strides in this industry, offering suborbital flights to civilians. Manufacturing space tourism vehicles involves rigorous testing and quality control to ensure passenger safety.

Virgin Galactic’s SpaceShipTwo

Virgin Galactic’s SpaceShipTwo is designed to carry paying customers on suborbital flights to experience weightlessness and see the curvature of the Earth. The manufacturing of SpaceShipTwo involves meticulous attention to detail, with North American manufacturers ensuring that every component meets the highest safety standards.

The Role of Innovation in Manufacturing

One common thread running through all of these space events is innovation in manufacturing. North American manufacturers are constantly pushing the boundaries of what is possible, whether developing new materials, refining production processes, or implementing advanced quality control measures.

3D Printing in Space Manufacturing

One notable innovation is the use of 3D printing in space manufacturing. This technology allows for the rapid production of parts and components in the harsh space environment. Companies like Made In Space have been pioneering the use of 3D printing on the International Space Station, paving the way for more self-sufficient space manufacturing in the future.

Advanced Materials and Nanotechnology

Manufacturers are also exploring advanced materials and nanotechnology to create stronger, lighter, and more durable components for spacecraft. These materials are essential for reducing the overall weight of spacecraft, improving fuel efficiency, and enhancing the safety of astronauts.

Conclusion

As we look forward to the North American space events of 2024, it’s clear that manufacturing plays a pivotal role in turning dreams of space exploration into reality. From the colossal Space Launch System that will propel us to the Moon as part of the Artemis program to the innovative technologies used in commercial space ventures and the construction of the Lunar Gateway, North American manufacturing is at the heart of these cosmic endeavours.

Innovation, collaboration, and a commitment to quality are the driving forces behind these manufacturing efforts. As we witness humans return to the Moon and venture further into the cosmos, let us not forget the unsung heroes in the factories and laboratories across North America who make it all possible. The stars have never been closer, thanks to the dedication and expertise of those who manufacture the tools to reach them.