This is always a great question: How do I become a Tool and Die Maker. Normally, when you get asked that question, you’re being asked by a young person either full of excitement because they have found their vocation and can’t wait to get started, or you get a look full of tribidation staring back at you saying I guess that’s good enough what’s involved in tool and die and how do I get started, they may just be afraid they’re going to miss out on the work of life little do they know life has only hard work waiting for the eager.

The key to becoming a Tool and Die Maker is finding a shop that will sponsor you for a tool and die apprentice. Okay you say, so how do I do that?!

There are multiple paths to an apprenticeship which include the typical school route and the harder work and time route. The most typical route to becoming a Tool and Die Maker in North America or mostly (southern Ontario and northwestern the United States) is by completing your high school education. It is an advantage if you focus on general math and any shop classes you can take in high school will serve you well. Focusing on the fundamental maths (geometry, trigonometry, scientific notation, adding, subtracting, fractions, etc.) will make your life easier, but it’s definitely not necessary to be a math wizard. Just have an open mind and be willing to work at developing the skills you are going to need for your career as a journeyperson tool and die maker. Not all high schools provide shop class anymore, but if your school does provide any vocational training and you intend to go into the trades, I would encourage you to take as many of those classes as you can. Doing so will start to expose you to tools and, most importantly, shop safety fundamentals, which are best instilled early.

Some high schools offer co-op placements which count towards the hours needed for an apprenticeship time in a particular trade. The highschool I went to in Ontario, Canada did this for Tool and Die. What that means is that for your last two years of high school you spend your afternoons at a job placement where you are to learn workplace skills for high school credits. This program then allows you to use your workplace co-op hours towards your apprenticeship requirement hours. This can shorten your apprenticeship by up to an entire year. It also makes it easier to find a shop to take you on as an apprentice, whether it’s where you had your high school placement, because they already have a relationship with you and are an apprentice oriented workplace, or another shop that appreciates the time you’ve already put in.

If your high school doesn’t offer a co-op program that’s okay, but if you’re keen on the trade, I would still encourage you to, to hand in your resume to any shops in your area, while in high school. Try to get any position in a shop that’s available, even if it is just offering to sweep up floors. Having your foot in the door at a shop early can save you time down the road, because if the shop you have been helping out at likes your work ethic and knows you’re smart and keen on the trade, they may sponsor you to become an apprentice for them. Even if the particular shop you are at isn’t able to provide an apprenticeship, which can be the case for a number of reasons, at least at this point in your trades career, you have a leg up on most other high schoolers. Already having some shop experience will be valuable in this next step after high school of finding a sponsor to start your apprenticeship.

Once you’re finished with high school, one of the paths to becoming a tool and die maker is to find a job in a shop, if you’re not already working at one, and for them to agree to sponsor you for your apprenticeship. If the shop you’re working in doesn’t meet the requirements for providing an apprenticeship, you should start looking at finding a job in one that can. (apprenticeship requirements). If you have no shop contacts and no previous experience in the Tool and Die Trade you can consider a pre-apprenticeship course in tool and die/machining. These courses aim at teaching you employable technical skills, as well as resume writing and interview skills. This gives tool and die shops more reason to take you on, because someone willing to do a prep course is more likely to be committed and have the right attitude to work in a shop.

Here is a list of some resources for different regions of North America. As there are different standardized training requirements in different areas, most of this article is what is typical in Ontario, Canada.

List of colleges with Apprenticeship and pre-apprenticeship programs:

Ontario

https://www.ontariocolleges.ca/en/programs/professions-and-trades/tool-and-die-mould-maker

Provincial and Territorial Apprenticeship and Certification Authorities / Red Seal (red-seal.ca)

Ohio

https://apprentice.ohio.gov/contact/

https://omj.ohio.gov/program/Tool-and-Die-Makers.stm

https://apprentice.ohio.gov/careerseekers/#how

Illinois

https://www.apprenticeship.gov/

https://www.apprenticeship.gov/finder/listings?occupation=tool%20and%20die&location=

Pennsylvania

https://www.dli.pa.gov/Individuals/Workforce-Development/apprenticeship/Pages/default.aspx

Michigan

https://www.michigan.gov/leo/0,5863,7-336-94422_95539_73460—,00.html

What to expect once in the apprenticeship

Here in Ontario, the Tool and Die apprenticeship is 8000 hours over four years. In those four years, you will receive a binder where you will keep track of the minimum skills required to fulfill the standard to become a Tool and Die Maker by checking off each skill as you are trained and achieve competency in that skill. Normally there will be a journeyman in your shop assigned to monitor your progress as you work through the different skills in the binder. The assigned journeyman will have regular meetings with you to assess what skills can be signed off as sufficiently mastered.

Also during the four years of your apprenticeship here in Ontario Canada, you are required to do in-school training. This consists of a 12 week block of schooling in the first year followed by a 10 week block in both the second and third year. These schooling blocks were offered in two different formats during my apprenticeship. In my first year, we went to school for 12 weeks straight attending class from 9-5 Monday-Friday for one full semester. In my second and third years, I completed the 10 weeks of schooling in a different format. I attended class one day a week for an entire 8 month school year. The main reason I had to switch formats was because of my employer’s preference. Some shops give the apprentice the choice depending on his or her life situation.

In the first year’s format (12-week block) we had classes such as mechanical drawing and drafting, trade math, and trade theory. Normally half of the 12 weeks is working in the shop building your shop assignment project, which is normally the bulk of your semester’s mark. Our shop assignments in that first year were filing a block of metal square and flat to drawing specifications with a series of tapped and drilled holes in it, creating a tapered threaded spindle and, lastly, we also made v-block meeting specifications and tolerances from a drawing.

The second-year’s classes were more of the same including trade math, mechanical drawing, and trade theory. In the shop, our assignment was to make an indexing fixture meeting all the tolerances provided in the drawing.

The third-year classes were similar in that we had trade math and mechanical drawing but then there were 5 weeks of tooling theory, which was a little hectic and covered a lot of material. The shop project that year was building a small stamping die that produced a token that looked something like a bottle cap. In the third year, I found that attention to detail makes all the difference to your success. By being able to make the die accurately and maintaining proper alignment of all the punches by not accumulating any backlash error, one can finish with weeks even to spare. However, unless you have exacting precision you may be required to remake components for your die more than once due to error. So my recommendation is to take your time and plan your machining sequences.

The Test

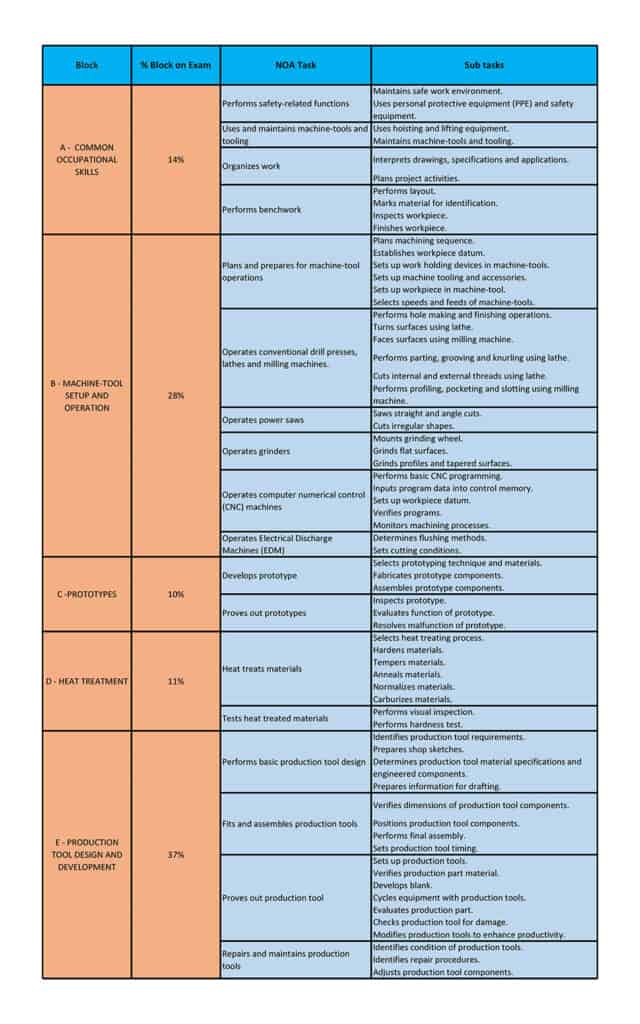

The 430-A Certification of Qualification test is the one that you will need to pass to get your Tool and Die Maker licence here in Ontario. To the best of my knowledge, it is the standard red seal trade test. Which is why the main purpose of this website is to try to help people prepare to pass this particular test.

What is involved in writing this test? The test is made up of 135 multiple choice questions that cover everything from all of the textbooks, the technical trade math, and the standard machining practices.

There will be a varying percentage of questions on each topic covered by the test the quantity of questions on each topic is weighted by importance. A passing mark here in Ontario is 70%. Once that is achieved on the C of Q test you will be awarded your Certificate of Qualification in Tool and Die, with interprovincial status “red seal”

Once you have passed your C of Q test, you are an official tool and die maker. Typically in North America, your apprenticeship sponsor will keep you on as a journeyman, but that may not always be the case and is worth knowing before starting your apprenticeship.

Thanks for reading this article on how to become a tool and die maker. Toolmaking and Machining strives to promote the trade and help the student succeed in their apprenticeship. If you would like more of this kind of content, please feel free to join our email list and check out some of our other articles that may interest you such as, The Stamping Die Build Process or How to Study for Your Tool and Die C of Q Test.